Using RFID

to Manage delivery

of Landfill Material

SageData is based in Ottawa, Ontario, Canada

Introduction

This note explains how RFID (or barcode technology) Can be used to manage the delivery

of landfill material

trucked to a building site or other location.

The problem is to ensure the quality of

materials delivered to

a building site. Large

quantities of fill material must be transported. The cost of the clean fill is high. The

cost of disposing of contaminated materials is also high, so there is profit to be made if

contaminated fill is used to replace the clean fill.

A double bonus

The cost of disposing of the contaminated fill is eliminated, and the substitute clean fill can be resold. But the risk to the developer is high. If a site is subsequently found to be contaminated, the value of the property is dramatically reduced, and high clean up costs may be incurred.

So how to avoid this?

There are measures in place to guarantee the quality of the clean fill. Testing and certification. The loading can be monitored. But the transport is unsupervised, and offers the opportunity for a diversion and substitution. Given that several hundred truckloads of fill may be required, management and protection becomes a challenge.

Current process

The situation is currently managed by employing security personnel to oversee the load and unload process. Security personnel can vet the load, check the test certification, and time the departure and arrival of each truck. But this is time consuming, manual, and prone to error.

A better way

Computers have solved many problems in business, but here we are talking about an outdoor activity in a potentially harsh environment. SageData have experience of tracking truck loading and unloading activities in remote locations. This is just a slight variation on an existing theme.

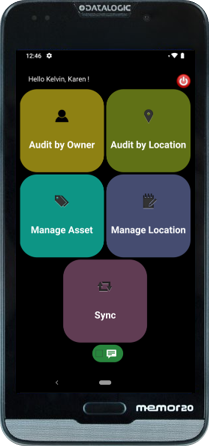

Rugged Handheld Computers

Handheld computers (mobile units) can be deployed at the load and unload sites. They can be connected via cellular network. The software simplifies data collection and decision making, which is important, as staff on the ground may change, which means the system must operate with minimal training.

The key issue is to identify each vehicle, and track the time of departure and arrival. By imposing a time limit for the journey, we deny the driver the opportunity for load substitution, as there will be no time for detour, unload and load.

How to identify the truck and or driver?

Perhaps the easiest is to hand the driver a PASS

that he must present at

the destination. The pass can be a small plastic card the size of a credit card. A unique

barcode on the card can be read by the handheld computers at each end. The computer tracks

the time, and can be set to make a go / no go decision for acceptance of each load. The

system can be sophisticated enough to allow for variations due to traffic conditions.

Reporting

Apart from reporting time for each load to be transported, the system can provided detailed activity reports by truckload.

Set up and configuration

The system would permit unlimited handheld computers to be used. Management would be able to track deliveries in real time through a simple web application. Set up is simple, as the system is accessed from any machine with a browser and internet connection. User names and password protect the system from unauthorized access.

Contact us for more information.

If you found this useful, you might also want to review:

-

managing construction equipment with RFID

- an introduction to RFID

- RFID in a warehouse - a brief video

-

active RFID tags

QAOK4356