Food Safety Software

How it works, how it is used, what it does

SageData is based in Ottawa, Ontario, Canada

This page describes the software used to help ensure food safety in a large industrial cooking

facility. It

describes the system, explains how it works, ways it can be used, and what it does to improve food safety.

Mobile Units are used to capture data, and barcode and RFID technology is used to track food containers and

temperature logging

tags. All steps in the process are monitored, from checking delivery vehicles for food safety hazards,

through tracking of

individual ingredients, contents of each batch as they are prepared, and checking storage conditions, to

preparation of food for

delivery, including checking against expiry dates.

The system provides essential information to be used when an ingredient is recalled.

One of the key requirements for food safety is traceability. Knowing what went into each batch,

and having the

ability to respond when a recall is made for a particular ingredient. SDS (SageData) have developed a system

which tracks all

ingredients from receipt through prep, cooking, storage and distribution. It enables the recovery of any

food affected by the

recall.

When there is a mass food production making sure that food making is safe is mandatory. For starters, one needs to know the recipes, measure the raw ingredients, cook, store properly and deliver when required. There is also a process of receiving the ingredients, logging the supplier and the lot data to ensure this information is available in case of food recall or an investigation. In short, this is a complex and multi-phase process that requires proper management.

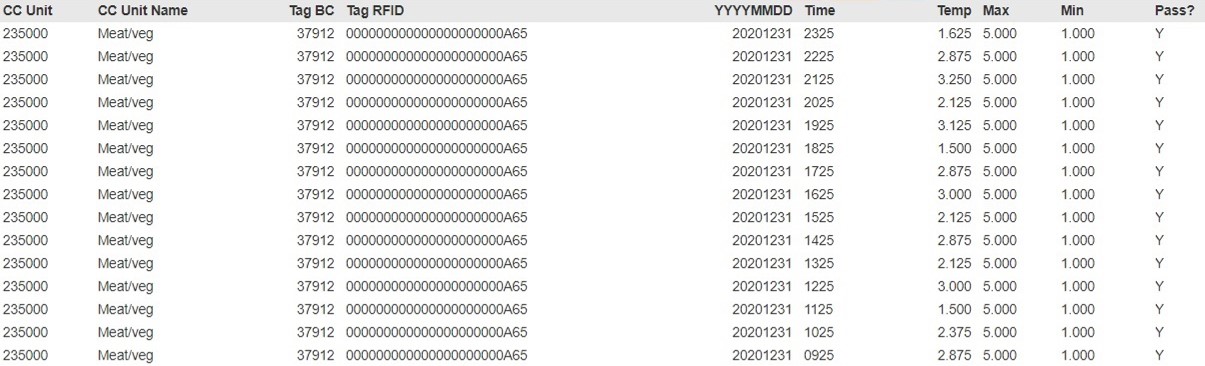

SagaData Solutions built and implemented a system that manages food safety control processes for approximately 20 thousand people. The foundation of this system is our renown BassetPro software solution in combination with Barcode and RFID technologies and mobile information collectors. Below is a sample of an automated RFID tag-based temperature measurements report.

Our system enables round the clock food production processes across multiple centers. The food

production staff is

provided with user friendly tools to:

- Set up new recipes, food ingredients, suppliers, etc. or updating the existing ones

- Receive the ingredients at dedicated food production centers

- Pick up proper ingredients based on the targeted recipe

- Store cooked food at appropriate temperature ranges by measuring the temperature within food container,

and comparing it with a

preset range

- Deliver exact food quantities for distribution

- Ensure that the cold chain is adhering to the set standards by measuring the ambient temperature, and

comparing it with a

preset range

- View and print reports for various production stages and ranges of time

We would be delighted to share our experience and lessons learned with you. The above-mentioned system could be easily adapted to manage a manufacturing or any other process involving multiple components and processing stages.

If you found this useful, you might also want to review:

- an introduction to

barcode technology

- an introduction to RFID

- RFID temperature logging - a brief video

- an introduction to applications

QAOK5359