Fixed Assets, How to Manage Them, An Introduction

SageData is based in Ottawa, Ontario, Canada

Definition

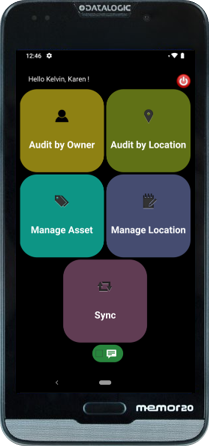

Asset management systems track individual physical items.

These are usually identified with a UIC (Unique Identification Code), which in most cases is

encoded

either in

barcode format on an asset identification label, or by means of an RFID tag. Handheld

computers with integrated barcode readers are used to perform audits, or to track movement of

items.

The

systems generally include detailed reporting functionality, and can exchange

information with back end systems, such as SAP or Oracle.

These are usually identified with a UIC (Unique Identification Code), which in most cases is

encoded

either in

barcode format on an asset identification label, or by means of an RFID tag. Handheld

computers with integrated barcode readers are used to perform audits, or to track movement of

items.

The

systems generally include detailed reporting functionality, and can exchange

information with back end systems, such as SAP or Oracle.

What can be tracked?

These systems are used to track a wide variety of items - anything physical, that has value, that is operationaly important, or which has security implications.

IT Asset Management is a very common application, particularly within larger

organisations,

such as the

Federal Government.

Some organizations use an asset management system to track all IT equipment in the, managing

these

items from receipt through deployment, redeployment and

maintenance (scheduled and unscheduled), through to return at end of lease.

Critical Equipment in a manufacturing environment can be tracked for calibration purposes,

or

for

production planning.

Secure documents can be tracked in transit or when issued and returned to a secure storage

location.

Safety Equipment, including fire extinguishers and other fire prevention equipment can be

audited and

inspected.

Tools can be tracked as they are issued and returned to a tool crib.

Vehicles, radios and other items issues on a shift by shift basis can be managed

effectively.

Linkages

Many linkages are possible, but most systems rely on linking people, places and things - each asset is identified as being in a specific physical location, and the responsibility of a specific individual.

Receiving

Systems track the original receipt of an item, and a clone function simplifies data entry, which can be done on a desktop or mobile data collector.

Audit

Audits can be completed quickly, easily and accurately. The use of a barcode on the

asset

identification

label, and a handheld computer (with integrated barcode reader) to read those

labels, means that it takes less than a second to audit each asset.

Because locations can be identified in a similar fashion, mistakes are reduced.

Because all transactions are timestamped, and data entry is automated, (through the use of the

barcodes

and scanners), data integrity is high. Users can have a great deal of faith in the

accuracy of the final reports.

Disposal

Disposal is tracked by the system, is fast, and is accurate. Specific notes can be attached, or standard client documentation can be easily integrated into the system.

Maintenance

Maintenance can be tracked by the system, maintaining an accurate historical record. Again, bar codes guarantee accuracy, and guard against abuse. A planned maintenance function enables future activities to be planned.

RFID for Asset Management

This technology offers some distinct advantages in key areas. It is powerful for file tracking. It can be used to track IT equipment, making the audit process far more efficient. And it is a natural solution where large items need to be tracked, especially in an outdoor environment.

Working with your existing systems

Most applications have import and export capabilities so that they can work with your existing systems. From the reliability and maintainability viewpoints, most organizations opt for a standalone system that can exchange information with the existing ERP and accounting systems.

Contact us to discuss your asset management needs.

For further information browse the following pages:

- introduction

to

barcode technology

- RFID technology overview

- BassetPro software

introduction

- mobile data collectors /

handheld computers

QAOK5358